How To Make Melamine Dinerware

2024-04-10

The process of making melamine dinnerware typically involves a combination of melamine resin, which is a type of thermosetting plastic, along with other materials to achieve desired properties such as durability, heat resistance, and color.

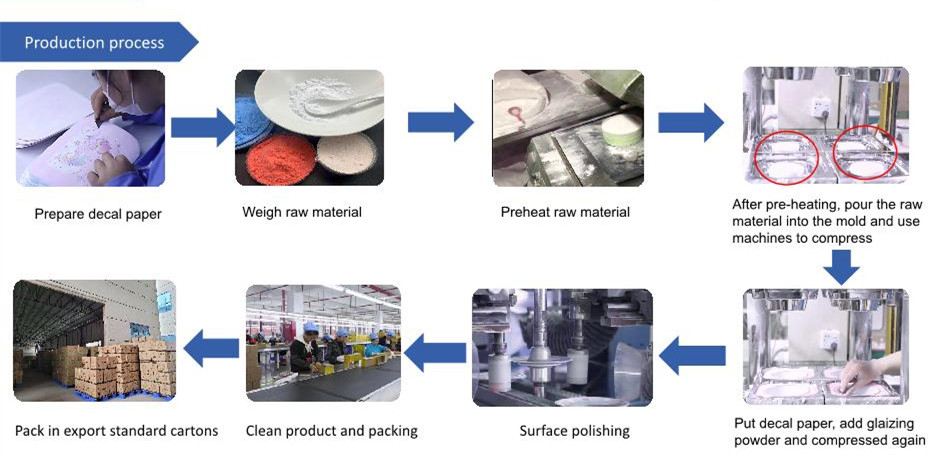

The general process involves:

Mixing Ingredients: Melamine resin is combined with other additives such as formaldehyde, fillers, pigments, and sometimes fibers to create a melamine compound.

Molding: The melamine compound is then poured into molds of various shapes and sizes to form the desired dinnerware items such as plates, bowls, cups, and utensils.

Pressing and Curing: The filled molds are subjected to heat and pressure to cure the melamine resin, which hardens and solidifies the material into the shape of the mold.

Finishing: After curing, the dinnerware items may undergo additional finishing processes such as trimming excess material, smoothing edges, and applying surface treatments or decorations.

Quality Control: Finished products undergo quality control checks to ensure they meet standards for safety, durability, and appearance.

While there may not be recent news specifically about the manufacturing process of melamine dinnerware, you can find information about the industry, trends, regulations, and innovations related to melamine products by searching industry publications, trade journals, or websites specializing in materials science, plastics manufacturing, or kitchenware manufacturing.

Get the latest price? We will reply as soon as possible (within 12 hours)